Research into high entropy alloy (HEA) coatings paves the way for the development of surface engineering

11-12-2024

Because of their properties, high entropy alloys (HEAs) are of great interest to researchers. A group of researchers from NCBJ's Laboratory of Plasma Surface Engineering is testing the use of this type of material in the form of thin films. An article on this topic has just been published in the journal Metallurgical and Materials Transactions A.

High-entropy alloys (HEA) are a group of materials that are distinguished by unique physical, chemical and mechanical properties that are not possible with conventional metal alloys. Depending on the metals used, HEA alloys can exhibit very high hardness, wear resistance and corrosion resistance. For this reason, they are the subject of research by many groups of scientists. One possibility for using this type of material is to create thin films applied to substrates made of other substances. A number of techniques are known in materials engineering to produce such coatings, including electrochemical deposition, pulsed laser deposition or laser surface alloying. Another method for creating thin coatings is pulsed magnetron sputtering (PMS), in which the layer is applied as a vapour during short electrical pulses. This is the method used by researchers at the Laboratory of Plasma Surface Engineering of the NCBJ's Plasma / Ion Beam Technology Division, who specialise, among other things, in the synthesis of high entropy alloys and other advanced materials such as nitride and oxide semiconductors.

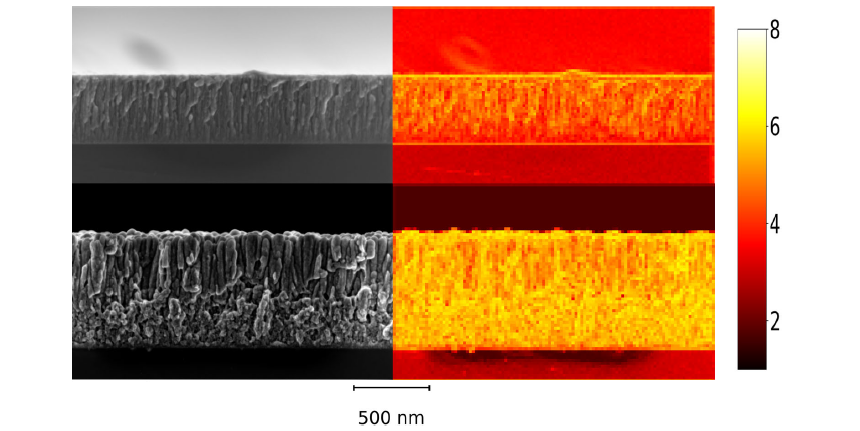

In their latest work, a team of researchers examined the effect of frequency modulation of the PMS process on the homogeneity and properties of alloys containing titanium, chromium, iron, cobalt and nickel (TiCrFeCoCr). "The frequency and lifetime of plasma pulse generation during the PMS process is a key parameter for synthesis" - describes Grzegorz Strzelecki, M.Sc., first author of the publication. "The study has shown that appropriate modulation frequencies enable the production of extremely homogeneous layers with the desired mechanical and structural properties, which opens up new possibilities for precision materials engineering." Based on analyses of both the surface and cross-sections of the resulting layers, the researchers were able to identify a range of modulation frequencies that allows the simultaneous production of a highly complex surface without losing the uniformity of the coating.

A completely novel element of the research was the use of Shannon entropy in the analysis, which is a concept used in information theory. In this field, entropy is a measure of the average amount of information per single message from an information source and can be interpreted as the uncertainty of the occurrence of a given event. "In the case of materials research, the use of Shannon entropy allows us to measure the degree of randomness and complexity of the material structure" - explains the article's author. "This innovative method makes it possible to predict the efficiency of the synthesis process and optimise the properties of the obtained materials". The use of this quantity is particularly valid for HEA alloys, given their complexity and the possibility of varying microstructures, depending on the conditions during their synthesis.

The work of the specialists at the Laboratory of Plasma Surface Engineering not only contributes to a better understanding of high entropy alloys, but also opens up new avenues of research, such as the use of Shannon entropy for material characterisation. This type of research could pave the way for the development of robust coatings and layers ideal for use in demanding industries such as aerospace, medical devices and advanced wear-resistant technologies. "The work highlights the Laboratory's contribution to materials science - surface engineering, offering novel approaches to the synthesis and characterisation of highly-entropic alloys, with great potential for industries requiring advanced material solutions" - concludes Grzegorz Strzelecki.

The full results of the study are available in the paper:

Strzelecki, G.W., Nowakowska-Langier, K., Namyślak, K. et al. Shannon Entropy Characterization of High-Entropy Thin Films Synthesized by Pulsed Magnetron Sputtering: The Influence of Modulation Frequency. Metall Mater Trans A (2024). https://doi.org/10.1007/s11661-024-07643-x